![]() WHO WE ARE

WHO WE ARE

The PROFACTOR Group is based in Steyr, Austria. We develop new technologies, solutions, and products in the areas of production, nano technology, and energy.

![]() WHAT WE DO

WHAT WE DO

The most important for us is to enable innovation by leveraging the breakthrough of 3D application with the easy-to-use-principle of CANDELOR and ReconstructMe.

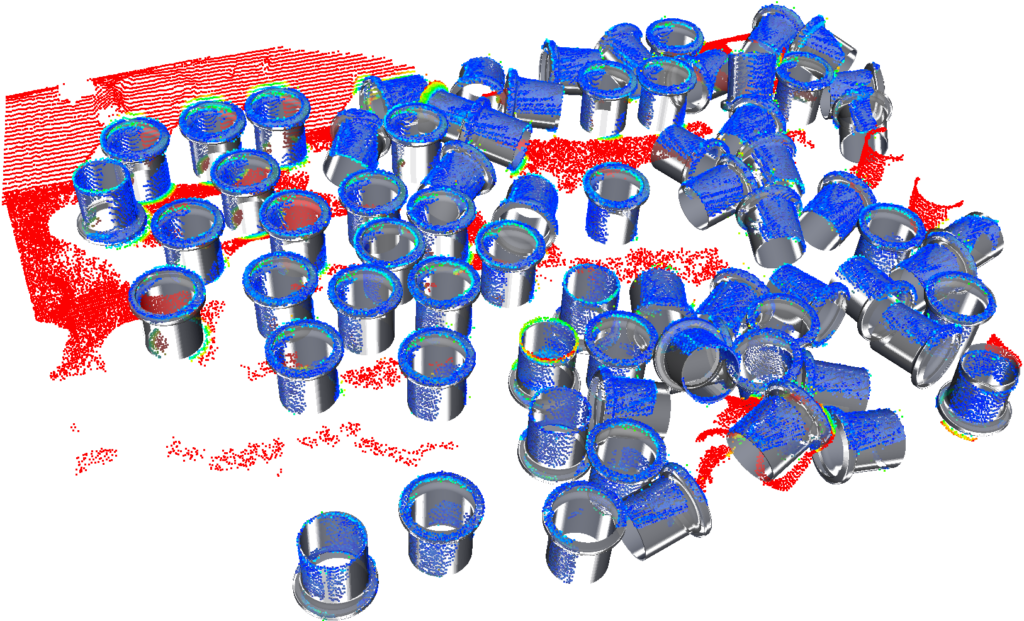

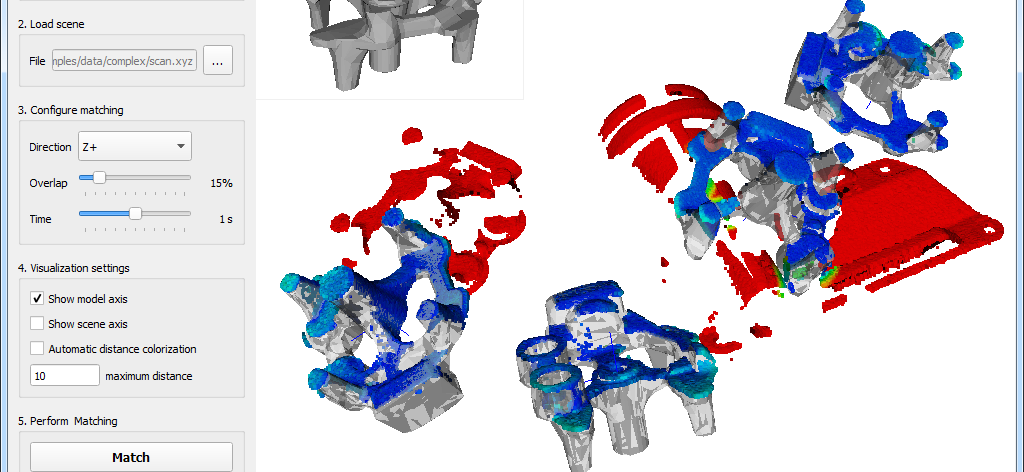

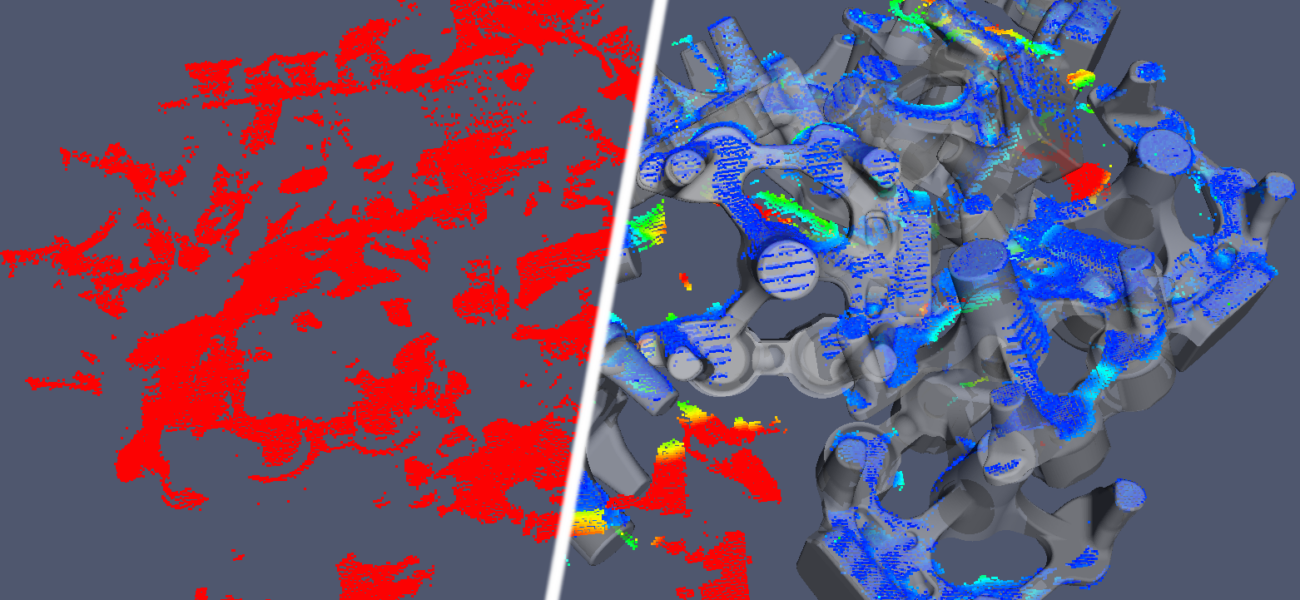

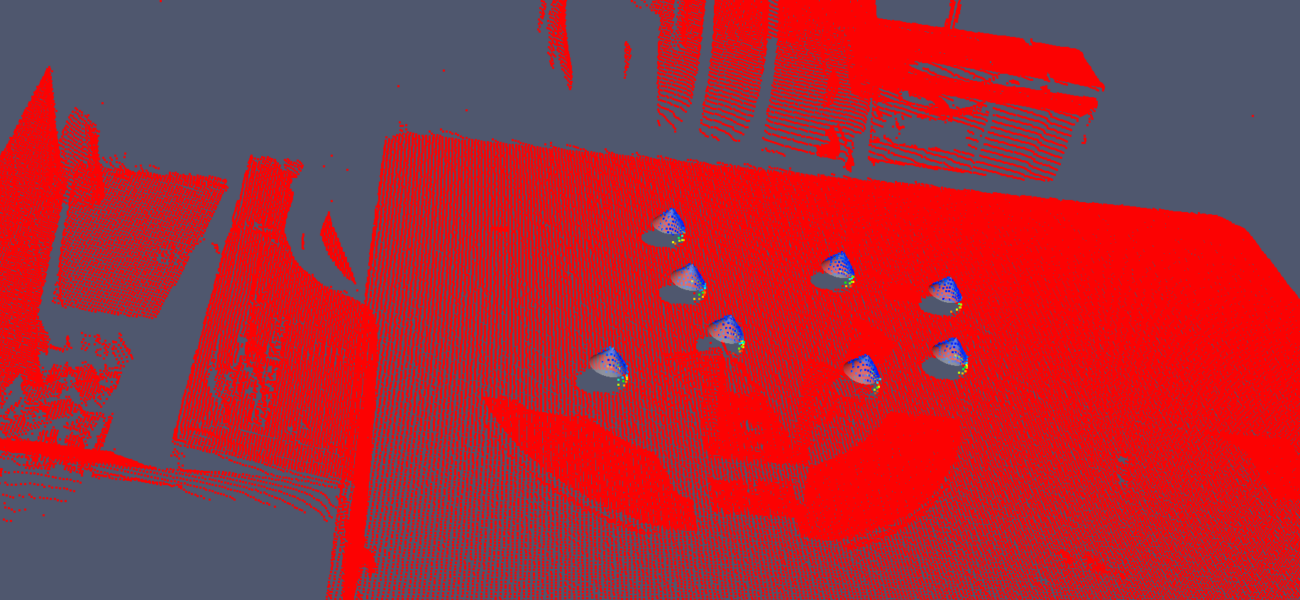

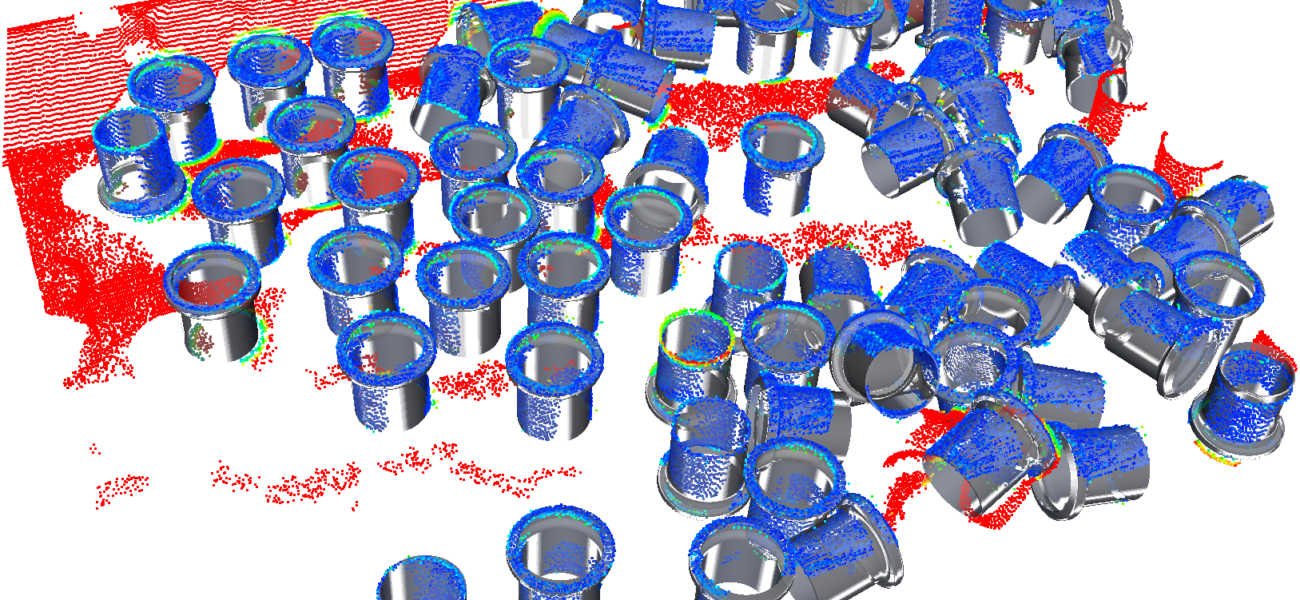

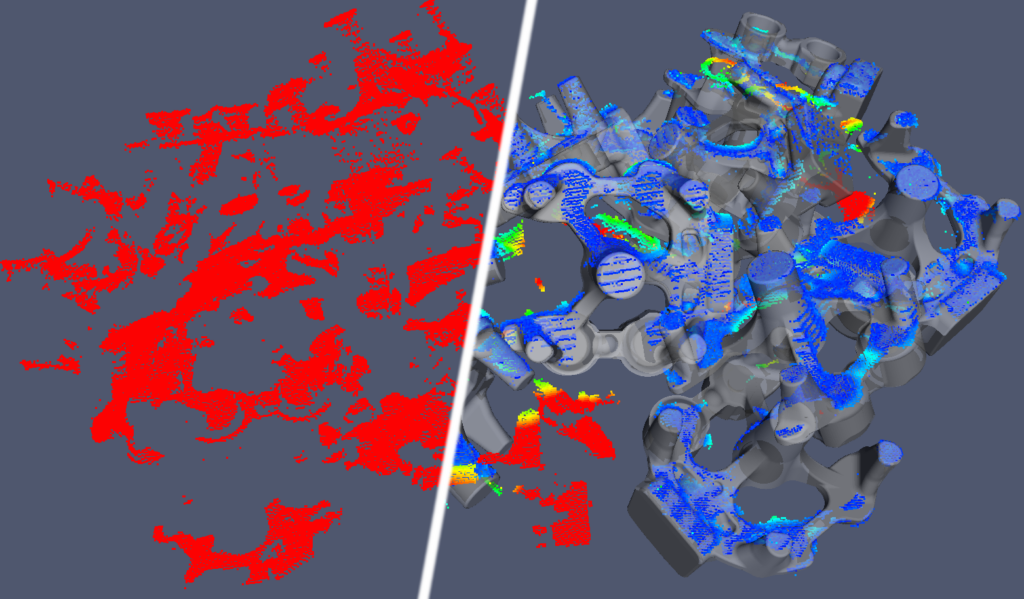

![]() WHAT IS CANDELOR

WHAT IS CANDELOR

CANDELOR is a solution for 3D scene interpretation. It contains a highly scalable, robust, and flexible 3D object localization algorithm.

![]() HOW TO GET IT

HOW TO GET IT

You can download a free full evaluation version of CANDELOR. Pricing models and evaluation version are available here.